AI In Inventory Management: A Complete Overview

Dipti Singhal

Sep 24, 2025

Traditional inventory management is being surpassed by AI in this area. AI is effectively changing inventory management through predictive analytics, demand forecasting, automated replenishment, reduced overstock, and stockouts. This blog discusses AI in inventory management along with advantages, applications, problems, solutions, and how artificial intelligence (AI) will transform the business landscape in the future as it relates to inventory management. It will enable you to expand your expertise and apply AI for improved company expansion!

AI inventory management is the process of automating and streamlining inventory management procedures with AI. Monitoring and regulating a company's stock levels is part of inventory management. In order to promote a convenient supply chain operation, AI inventory management makes sure that every product is in its proper location.

What is an AI Inventory Management System?

AI inventory management is a kind of practice that can automate and optimize and that can handle inventory operations. It can integrate with data analysis, predictive analysis, and machine learning (ML), so it can enhance ai inventory management software. It can handle any kind of operation, from supplier management to demand forecasting or replenishment. It can also work with AI trends that can complete inventory management in your business.

Businesses effectively maintain the right amount of goods in stock by using artificial intelligence in inventory management to satisfy customers' demands in real time by ai for inventory management. It minimizes holding costs and maximizes business profitability by reducing overstocks and stockouts and maintaining supply and demand alignment.

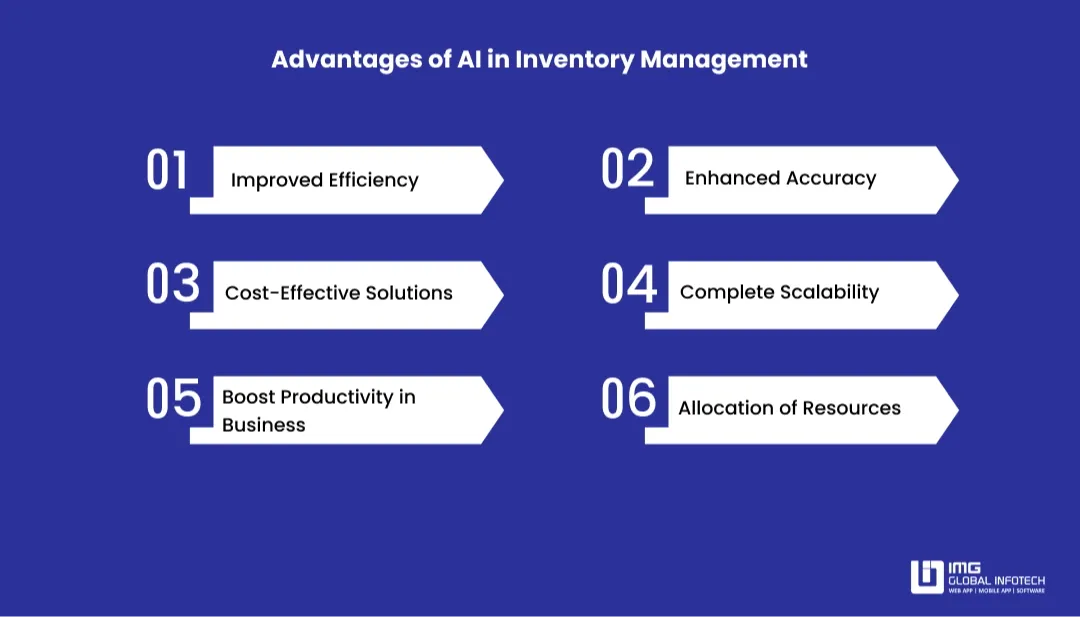

Benefits of Using AI in Inventory Management

Let’s take a closer look at several benefits of using ai based inventory management for your business:

1. Improved Efficiency

These AI-driven systems can streamline the inventory management, which can process for automating the monotonous tasks like analysis, decision-making, and data entry by artificial intelligence inventory management. It can also eliminate the manual effort in businesses that can allocate resources more expertly and that can focus on higher-value activities like customer service and strategic planning.

2. Enhanced Accuracy

The AI-driven algorithms can leverage the advanced data analytics to integrate with machine learning techniques that can process a massive amount of inventory data quickly ai order management. It can also eliminate the risk of human error from manual analysis and data entry work. It can load more precisely with inventory forecasts that can order recommendations with strategies for integrating ai in inventory management.

3. Cost-Effective Solutions

AI assists companies in cutting operational costs related to inventory management by optimizing inventory levels and minimizing carrying costs from machine learning inventory management. Businesses can maintain ideal stock levels by using AI-driven demand forecasting and inventory optimization algorithms in the use of ai in inventory management system, which eliminates the need for excess inventory storage and the related expenses.

4. Complete Scalability

AI-powered inventory management systems don't need a lot of human intervention to grow with the company or adjust to new demands and complexity in machine learning for inventory management. Knowing that their inventory management system can accommodate their changing business needs gives businesses the confidence to grow, enter new markets, or launch new product lines in inventory management using ai.

5. Boost Productivity in Business

Inventory management systems with AI capabilities increase productivity by automating tedious processes and offering useful insights from machine learning for inventory optimization. AI helps businesses grow and innovate by managing repetitive tasks like inventory tracking, replenishment recommendations, and demand forecasting, freeing up staff members to concentrate on higher-value work that can focus on ai in inventory management for manufacturing.

6. Allocation of Resources

AI-generated insights enable better decision-making regarding resource allocation in inventory management. For instance, ai for inventory management in restaurants reduce waste. By analyzing trends, patterns, and market dynamics, businesses can allocate resources more strategically, such as adjusting inventory levels, optimizing supply chain processes, and implementing targeted marketing strategies by gen in inventory management, leading to improved business outcomes and profitability.

Use Cases of AI in Inventory

AI-driven systems in inventory management handle several tasks like demand forecasting, inventory optimization, real-time inventory, automated reordering, and so on. AI can also help industries with anomaly detection, warehouse operations, and supplier management. Here is an index of use cases of AI in inventory management and how it can enhance your business growth and revenue as well.

1. Real-Time Visibility

Utilizing a combination of RFID & IoT sensors, real-time stock visibility, AI stock alerts, automated storage & retrieval systems (ASRS), and much more, Artificial Intelligence uses real-time visibility into where inventory is located.

Internet of Things networks consisting of physical entities like inventory items are outfitted with sensors, software, and connectivity, allowing a broader scope of data collection and sharing.

2. Classification of Inventory

Using sensors, AI inventory management can track items according to weight, temperature, location, motion, etc., and organize the products in the inventory in the most effective way. Automating at that level organizes and manages many products with minimal effort from AI software development companies for your business as well.

When items in inventory are categorized and organized, companies gain the ability to maximize storage, expedite retrieval tasks, and facilitate better decision-making for restocking and allocations.

3. Management of Returns

AI inventory management enhances the speed of returns management by analyzing returned products, spotting trends, and estimating return rates. It automates the processes by classifying returns, optimizing replenishment, and discovering quality-related issues.

This very process feeds into better decision-making, reduces costs related to returned items, and improves customer satisfaction through efficiencies in reverse logistics.

4. Warehouse Operations

By putting the capabilities of AI-powered sensors like RFID and IoT in supply chain management and automation solutions, AI collects real-time data and optimizes warehousing operations such as warehouse design, fulfillment process, etc., to find AI app development cost. AI optimized the layout of warehouses, optimized resource allocation, and automated tasks such as pallet racking and material handling.

AI algorithms also analyze data regarding demand trends, product sizes, and turnover rates and suggest the best storage feasibility for the warehouse. The AI systems provide real-time data on warehouse operations and inventory levels to spark proactive decision-making.

5. Scenario Simulation

AI-enabled scenario simulation enables organizations to simulate different market scenarios and assess their implications on various inventory levels. It is this capability that enables organizations to anticipate changes in market demand and develop flexible inventory strategies to quickly respond to ever-changing market demands and conditions.

6. Supplier Management

Artificial Intelligence analytics tools enable an in-depth examination of supplier performance measures. Such tools can objectively evaluate elements such as timeliness of deliveries, quality, pricing, etc.

Leveraging AI analytics enables businesses to plan strategically with suppliers based on data insights so as to ensure the right amount of inventory at the right level of capacity. Active management of suppliers aids in the procurement cycle, minimizes lead time, and reduces the risk of overstocks and understocks for business profitability.Procurement automation makes this process even smoother by using AI to handle orders, approvals, and supplier communication, cutting down on manual work and speeding up the supply chain.

7. Freak Detection

In inventory management, AI uses machines to detect anomalies such as stock imbalances, unexpected demand volatility, or supply disruptions to Build AI chatbots for managing operations in your business. Machine learning algorithms analyze a huge volume of real-time datasets triggered by IoT sensors and historical patterns to unearth anomalies, sending alerts to further reduce inventory errors.

This level of efficiency in anomaly detection means that businesses can take immediate action on a potential problem while continuing to preserve integrity and operational efficiency at every point of inventory levels.

8. Demand Forecasting

Inventory management powered by artificial intelligence facilitates the company's ability to respond to fluctuations in the market dynamically. AI algorithms will evaluate market trends, customer behavior, historical sales figures, social media, etc. to predict future demands with great accuracy by AI tools. This is called demand forecasting and allows businesses to plan their inventory levels without the risk of overstocking or being out of stock based on promising sales forecasts.

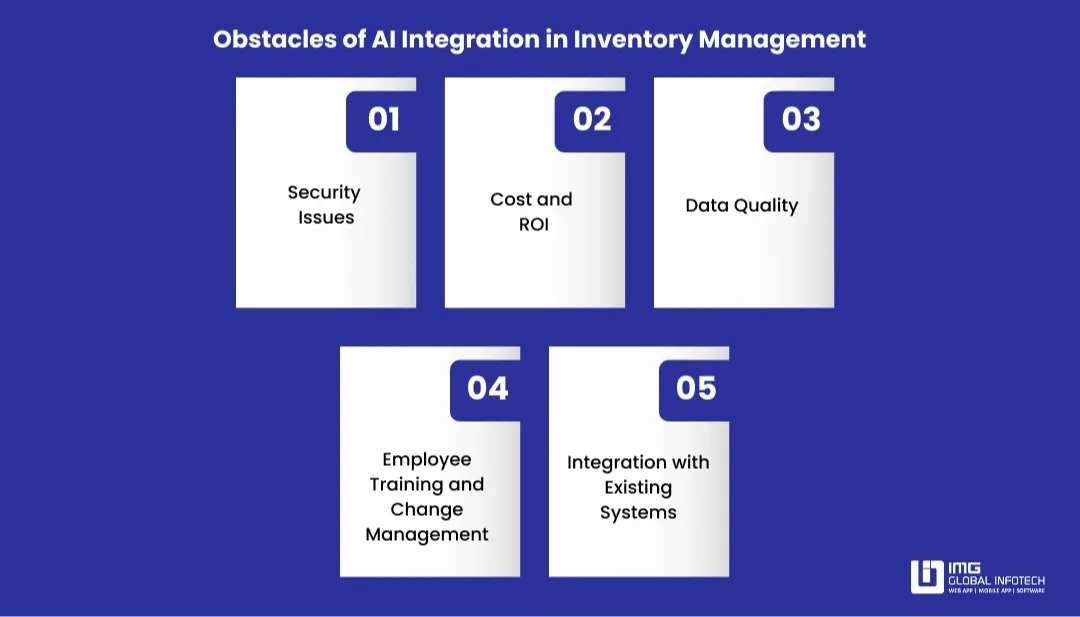

Challenges of AI Integration in Inventory Management

Let’s take a closer look at the challenges of AI integration in inventory management for your business.

Security Issues

With AI systems processing sensitive information, such as sales patterns, vendor details, and customer information, they become potential targets for cyberattacks. Companies must invest in solid cybersecurity systems to safeguard their AI-based inventory systems against data breaches and security attacks.

Cost and ROI

Implementing AI systems usually involves understanding the costs of implementation, which can be quite steep for small and medium businesses. Businesses need to consider the initial costs versus the extended benefits, including saving on labor expenses, increased efficiency, and enhanced stock optimization for Generative AI tools. It's important to calculate the ROI of AI adoption to assess if it is a worthwhile investment.

Data Quality

AI depends on data to operate properly, and low-quality data will produce inaccurate predictions and decisions. Having clean, correct, and current data is a decisive factor in the successful implementation of AI for inventory management. Companies must invest in the right data collection and verification processes in order to gain the full benefits of AI.

Employee Training and Change Management

Adopting AI into the process of inventory management allows workers to adapt to new systems and processes. Training is crucial as well as ensuring change management in order to guarantee workers' ability to utilize the new technology effectively and accept the changes brought by AI. A well-trained workforce may be able to facilitate the successful implementation of AI systems.

Integration with Existing Systems

One of the greatest challenges for companies is implementing AI within their current inventory management systems. Careful planning and cooperation among IT, operations, and vendors are necessary to accomplish this. Transitions must be seamless to prevent any glitches in inventory processes and ensure business continuity.

Future Trends of AI in Inventory Management

AI will drastically change inventory management in the future, surpassing current automation and predictive analytics. Systems that can drive efficiency, resilience, and strategic advantage across global supply chains will be hyper-connected, autonomous, and adaptable, defining the business landscape. And here's how!

Precision Demand Forecasting

AI will be utilizing a wide variety of data sources, via market trends, real-time sales, weather patterns, social sentiments, and economic indicators, to forecast demand with levels of accuracy that have never been seen before.

In addition, machine learning models will continuously self-improve, reducing overstock and stockout risk through just-in-time inventory management strategies even with complex global Supply Chains.

Fully Autonomous Supply Chains

AI-enabled inventory management platforms will autonomously control inventory throughout procurement, warehousing, distribution, and so on. It will allow for real-time business decision-making with less intervention from humans.

These platforms will automatically provide orders, manage suppliers, and reallocate stock based on predictive modeling algorithms and live data in order to maintain optimal inventory levels of supply chains.

Real-Time, Multi-Warehouse Optimization

AI will generate automated coordination of inventory across warehouses and sales channels, making automated stock balances based on local demand, transit times to replenish saleable items, and overall costs. This will minimize unnecessary transfers and transportation costs while expanding product availability for organizational profitability.

Automated Physical Processes

Computer vision and robotics technologies combined with AI will control physical inventory counts, picking, and replenishing operations with speed and accuracy that humans cannot achieve. This will allow businesses to capture and reconcile inventory information instantly, providing real-time visibility of inventory.

Final Words

Through this blog, we have explored AI in Inventory Management, a complete overview. We have also talked about some core elements of AI in inventory management in this blog, such as the meaning, benefits, use cases, and major challenges in this procedure while adapting AI in inventory management for your business.

Now you have an idea about the integration of AI-powered systems in inventory management as per the needs of your business. As we are a leading AI app development company, we always provide you complete assistance with the integration of AI technologies in your inventory management business as well.

-

How to Develop a Trading Platform Like Robinhood? A Complete Guide

How to Develop a Trading Platform Like Robinhood? A Complete Guide

-

The Role of AI in Credit, Banking, and Investment Services: Trends Shaping the Future

The Role of AI in Credit, Banking, and Investment Services: Trends Shaping the Future

-

Hire Gold Investment App Developers: Cost, Skills & Benefits

Hire Gold Investment App Developers: Cost, Skills & Benefits

-

Thinking of Building a Fintech App? A Complete Guide to Features, Costs, and Success

Thinking of Building a Fintech App? A Complete Guide to Features, Costs, and Success

-

Top 10 Logistics Software Development Companies to Hire in 2026

Top 10 Logistics Software Development Companies to Hire in 2026

-

Top Fintech Apps in India in 2026

Top Fintech Apps in India in 2026

Dipti Singhal is a skilled Content Writing Specialist at IMG Global Infotech, with strong expertise in creating engaging, SEO-optimized content for various industries. She focuses on blending storytelling with effective keyword strategies to help businesses connect with their audience and improve their online visibility. Passionate about delivering high-quality content that drives real results, Dipti plays an essential role in strengthening the company’s digital presence.